Welded H-beam

Classification :

PRODUCT DETAILS

Keywords: BY Steel Structure

H-shaped steel has two production methods: hot rolling forming and welding combined forming. Welding H-shaped steel is to cut strip steel with appropriate thickness into appropriate width, and weld the edges and waist together on a continuous welding unit. Welded H-shaped steel is named because the welding process is used to produce an H-shaped cross-section. It is divided into submerged arc welded H-shaped steel and high-frequency welded H-shaped steel. The process of submerged arc welding H-shaped steel is: steel plate - automatic striping - assembly - automatic submerged arc welding - flaw detection - flange correction - web correction - end face processing - sand blasting and rust removal - painting .

The fully automatic submerged arc welding production line's cutting, assembly and welding are all controlled by microcomputers to ensure that the dimensional accuracy of the H-shaped steel produced and the quality of the welds meet national standards.

HONOR QUALIFICATIONS

Chentai Quality System Certification

ISO 9000

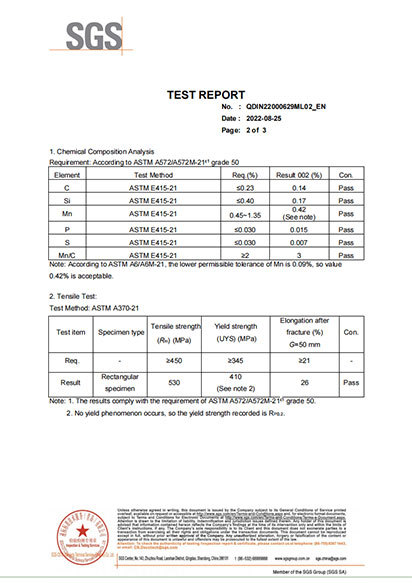

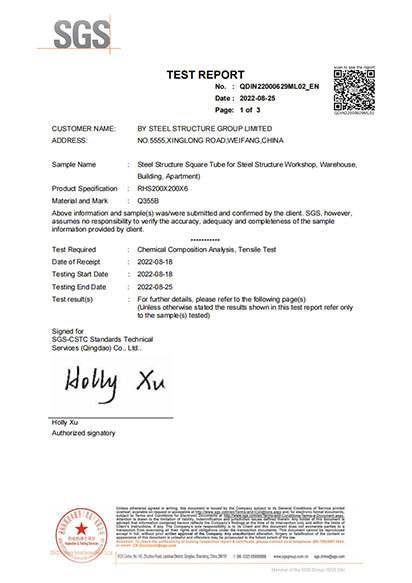

SGS-certificate-based-on-American-standard

SGS-certificate-based-on-American-standard

SGS

CE.002020191224

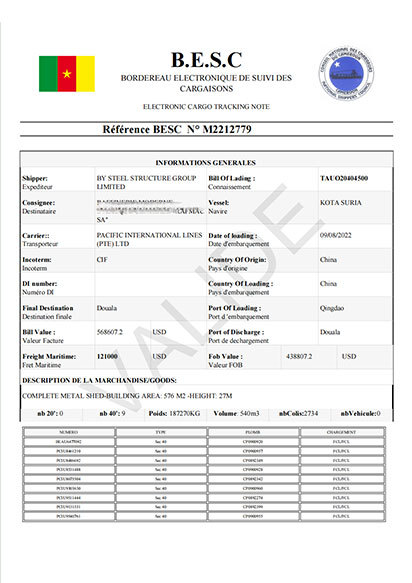

BESC

CCIC

CUSTOMER VISIT

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

QUALITY INSPECTION

Steel-packing

Measure-the-panel-width

Roof-sheeting-thickness-checking

Nondestructive-testing-2

Clients-inspection

Item-numbers-on-the-products

Fillet-weld-effective-throat-check

Film-adhesion-test

FACTORY WORKSHOP

factory

factory

factory

factory

factory

factory

factory

factory

FAQ

Q1: Are you a manufacturer?

Q2:Can we visit your factory ?

Q3: Do you have quality control?

Q4: Can you arrange the shipment?

Q5: How long is your delivery time?

Q6:How can we get the offer?

RELATED PRODUCTS

GET A FREE QUOTE