Galvanized and Galvalume Steel Coils

Classification :

PRODUCT DETAILS

Keywords: BY Steel Structure

Galvanized steel is a type of steel that is coated with zinc for protection by an electroplating process. The galvanized layer is applied to cold rolled steel at low temperatures. So EG steel is also known as cold galvanized steel. Through electrolytic galvanizing, a uniform and dense zinc layer is finally formed on the surface of the steel, but the mechanical properties of the material are still maintained. Electrogalvanized steel is usually sold in coil or sheet form. EG coil is a kind of material that can be cut, slitted and profiled for other purposes.

The steel grade of galvanized steel consists of base metal grade, galvanized (E), galvanized layer type and weight. The electro-galvanized products based on SPCC, SPCD, SPCE, SPCF and SPCG are named SECC, SECD, SECE, SECF and SECG respectively.

Scope of Application

Building Materials Field

Electrogalvanizing has a wide range of applications in the field of building materials. First of all, electro-galvanizing can be used to manufacture construction steel, which not only prevents metal oxidation and prolongs its service life, but also enhances the toughness, strength and corrosion resistance of steel, and improves the performance of steel. Secondly, in the decoration of building exterior walls, electro-galvanized aluminum alloy, electro-galvanized iron alloy and other materials are also widely used, which can protect the steel structure and prevent oxidation, but also has the characteristics of beauty and fire prevention.

Automobile Manufacturing Field

Electrogalvanizing is also a commonly used material in the field of automobile manufacturing. Electro-galvanized coating can be used for surface protection and repair of automobile parts to avoid oxidation corrosion and damage, and to improve the service life of automobiles. The electro-galvanized coating can also be used in the manufacture of parts such as car frames and casings to avoid oxidation and corrosion, and improve the overall quality and durability of the car.

Home Appliance Manufacturing Field

In the field of home appliance manufacturing, galvanizing also has its important applications. For example, the manufacture of refrigerators, washing machines and other household appliances shell, lining, refrigerator and other parts, usually need to use electro-galvanized material for surface coating, to prevent metal oxidation, improve appearance and performance.

Product parameters

| Product Name | Galvanized Coil |

| Thickness | 0.12mm-3.5mm |

| Width | 600mm-1500mm |

| Length | 508mm/610mm, Support Customization |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Zinc Layer | Hot Galvanizing: 60-275g/m² |

| Pre-galvanized: 80-275g/m² |

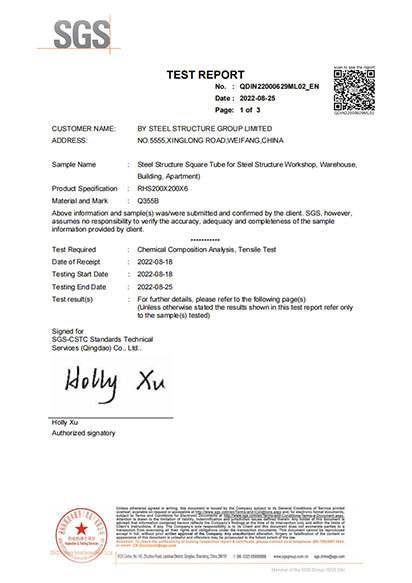

HONOR QUALIFICATIONS

Chentai Quality System Certification

ISO 9000

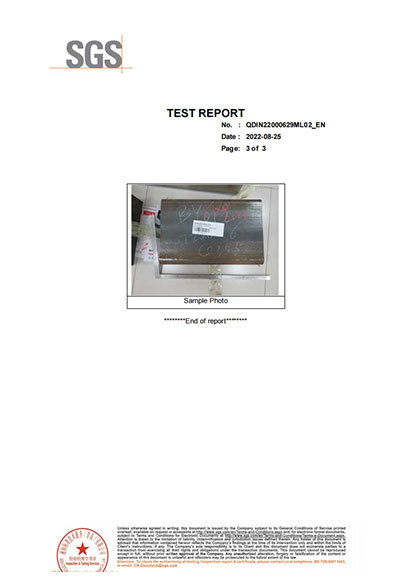

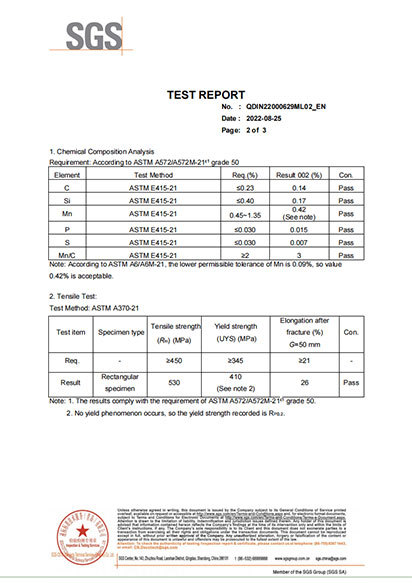

SGS-certificate-based-on-American-standard

SGS-certificate-based-on-American-standard

SGS

CE.002020191224

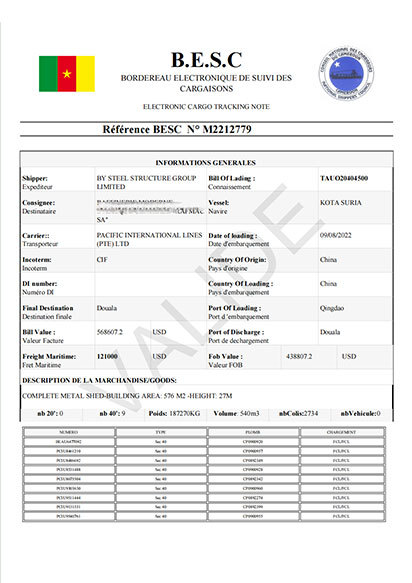

BESC

CCIC

CUSTOMER VISIT

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

QUALITY INSPECTION

Steel-packing

Measure-the-panel-width

Roof-sheeting-thickness-checking

Nondestructive-testing-2

Clients-inspection

Item-numbers-on-the-products

Fillet-weld-effective-throat-check

Film-adhesion-test

FACTORY WORKSHOP

factory

factory

factory

factory

factory

factory

factory

factory

FAQ

Q1: Are you a manufacturer?

Q2:Can we visit your factory ?

Q3: Do you have quality control?

Q4: Can you arrange the shipment?

Q5: How long is your delivery time?

Q6:How can we get the offer?

RELATED PRODUCTS

GET A FREE QUOTE