Curtain Wall T-Shaped Steel

Classification :

PRODUCT DETAILS

Keywords: BY Steel Structure

Curtain wall T-shaped steel is a T-shaped steel supporting device for building curtain walls, including at least one column and at least one crossbeam fixedly combined together. The column and the crossbeam are both T-shaped steel. The column includes wing plates and webs. The web of the column The center plane of the plate thickness is located in the longitudinal vertical bisecting plane of the wing plate, and the wing plate and the web plate are fixedly combined by at least two plug welding points; the beam includes a wing plate and a web plate, and the web thickness of the beam The center plane is located in the longitudinal perpendicular bisector of the wing plate, and the wing plate and the web plate are fixedly combined with at least two plug welding points; the web plate of the column and the web plate of the beam intersect each other perpendicularly, and the The top surfaces of the column flanges and the top surfaces of the beam flanges are in the same plane. The support device of this utility model can only connect and assemble the steel sections pre-processed and formed in the factory at the construction site, or perform a small amount of welding to ensure the strength and installation requirements of the curtain wall, thereby improving production efficiency.

In recent years, the advantages of curtain wall T-shaped steel in construction have been brought into better and better use. Submerged arc welded curtain wall T-shaped steel is undoubtedly a good thing. Curtain wall T-shaped steel is light in weight, easy to transport and assemble, and easy to recycle, which is environmentally friendly. Good products also require good technology to support them. Take curtain wall T-shaped steel as an example. Sometimes it will deform due to some problems. So what can be done to avoid this problem? Now let’s talk about common prevention methods:

1. Make preparations for the stiffness and welds of the curtain wall T-shaped steel, so that the entire steel section can be harmonious as a whole instead of highlighting a single function.

2. Pay attention to the welding sequence of section steel, such as welding the main welds first and then welding the secondary welds or welding the ones with large shrinkage first, etc. Develop a reasonable welding sequence so that the entire process can proceed in an orderly manner.

3. For some larger-sized steel sections, methods such as segmentation, layering, and intermittent welding can be used. When these methods are implemented, the frequency and speed of the high-frequency current must be controlled so that they are always at Same status.

4. If there is asymmetry in a large steel component, the steel components that make up it must be corrected first, and then assembled and welded to ensure overall stability.

HONOR QUALIFICATIONS

Chentai Quality System Certification

ISO 9000

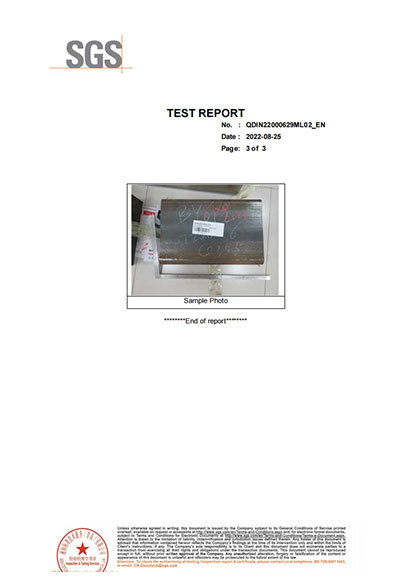

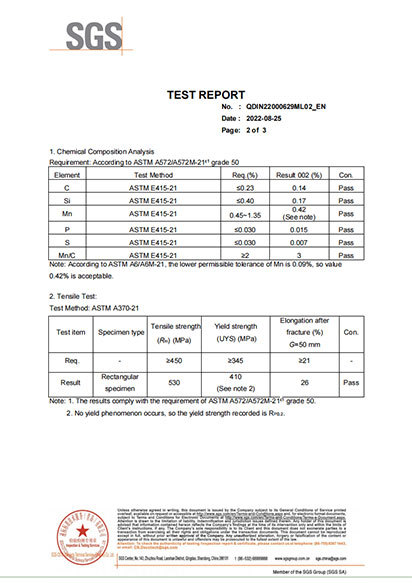

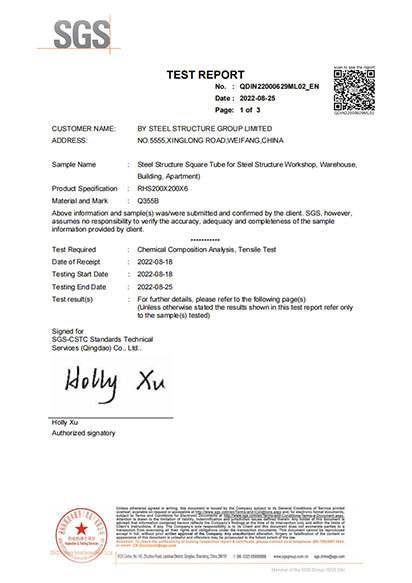

SGS-certificate-based-on-American-standard

SGS-certificate-based-on-American-standard

SGS

CE.002020191224

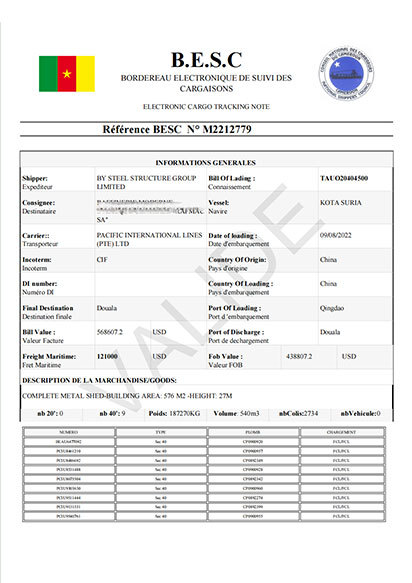

BESC

CCIC

CUSTOMER VISIT

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

QUALITY INSPECTION

Steel-packing

Measure-the-panel-width

Roof-sheeting-thickness-checking

Nondestructive-testing-2

Clients-inspection

Item-numbers-on-the-products

Fillet-weld-effective-throat-check

Film-adhesion-test

FACTORY WORKSHOP

factory

factory

factory

factory

factory

factory

factory

factory

FAQ

Q1: Are you a manufacturer?

Q2:Can we visit your factory ?

Q3: Do you have quality control?

Q4: Can you arrange the shipment?

Q5: How long is your delivery time?

Q6:How can we get the offer?

RELATED PRODUCTS

GET A FREE QUOTE